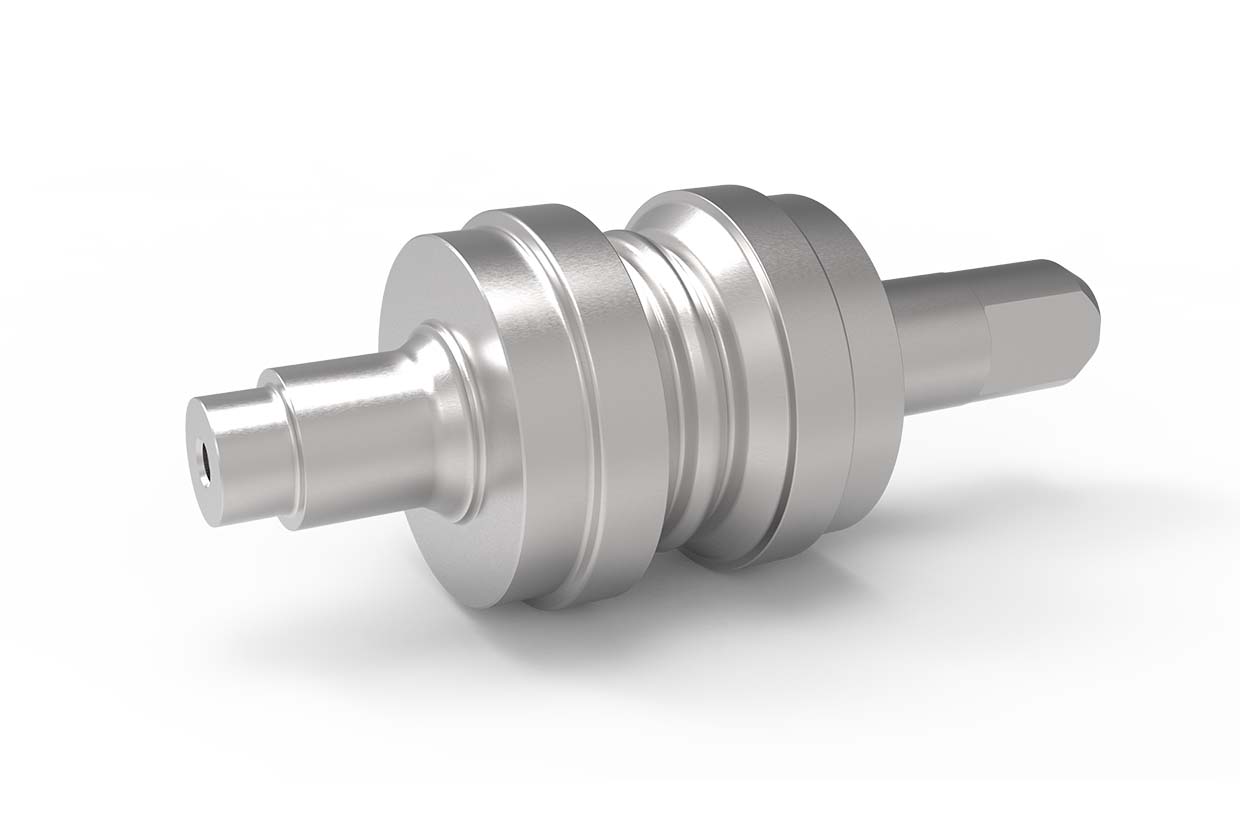

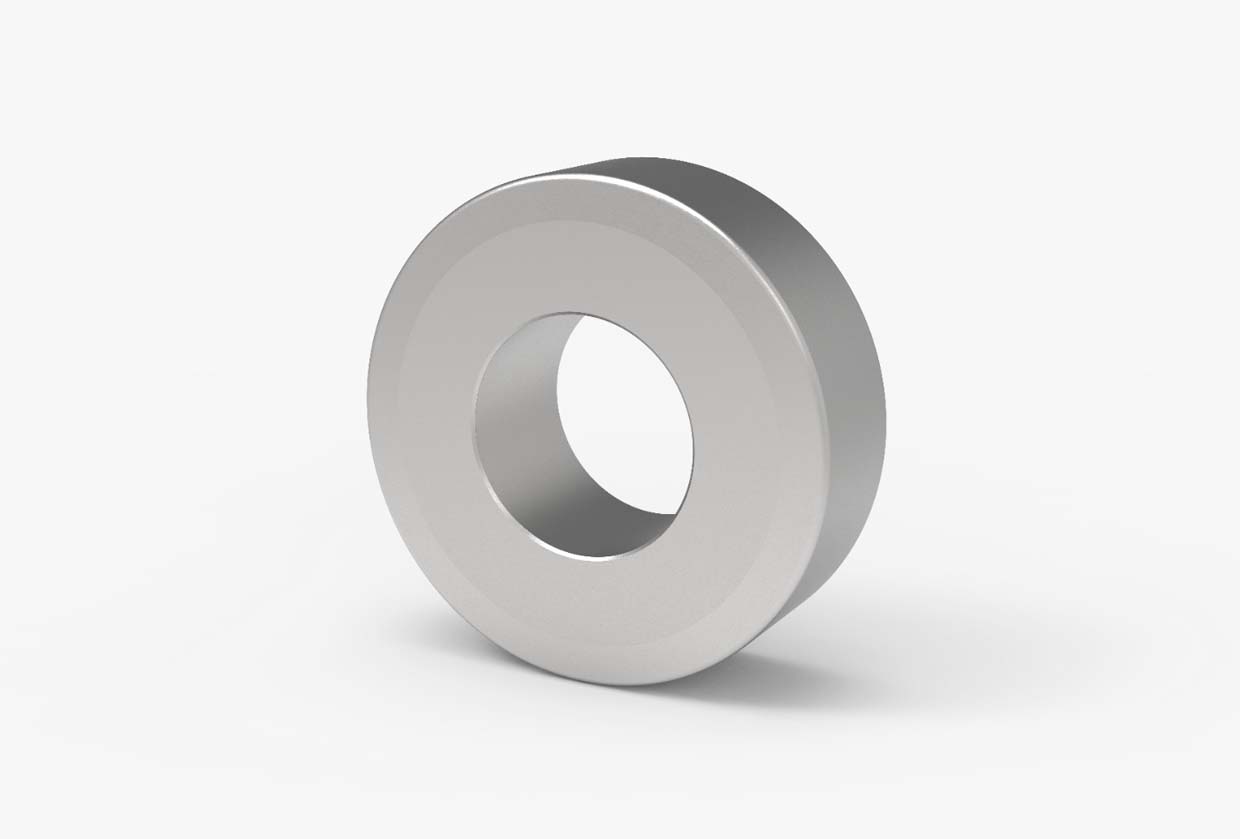

Metal Rolls For Rolling Mills

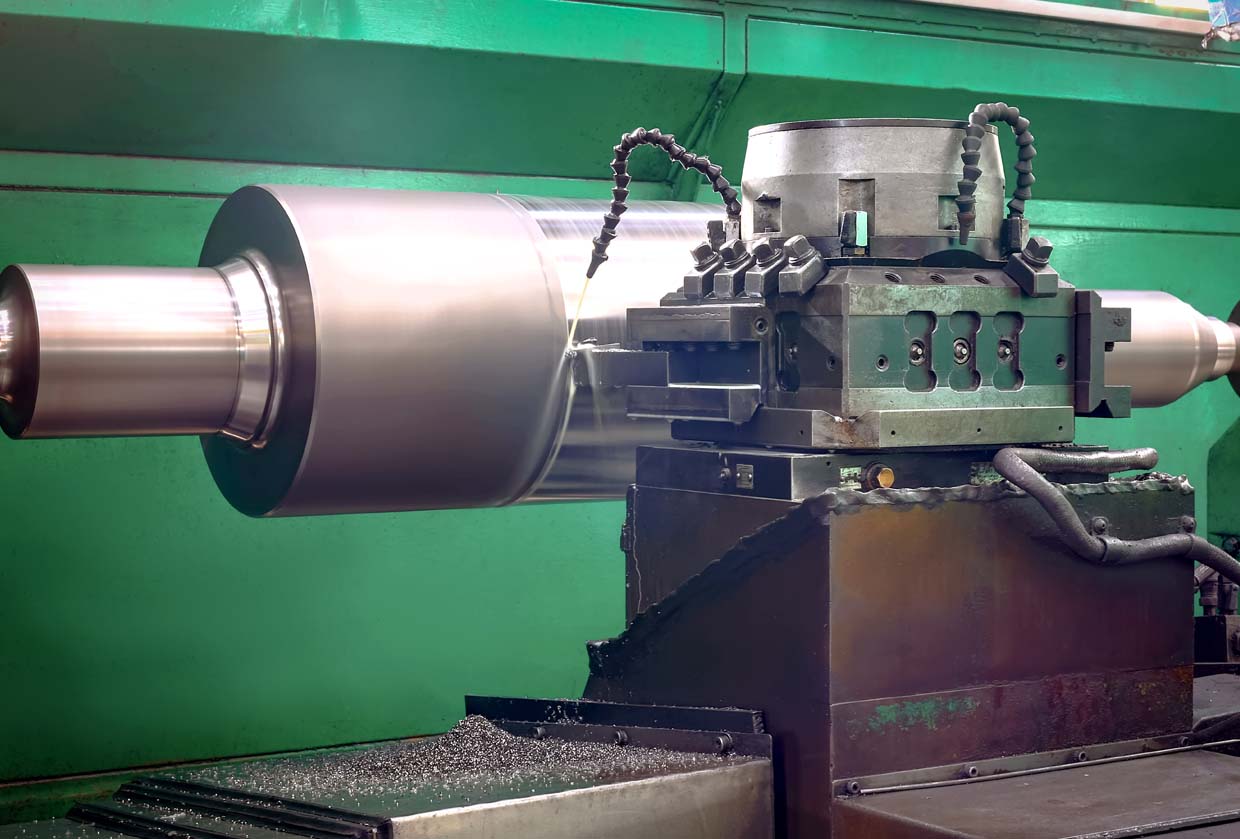

We are engaged in Manufacturing of Rolls for Rolling Mills in various grades, designed and customised so as to cater to our customer’s needs. Behari Lal Rolls has emerged as a strong performer when it comes to competence, efficiency, performance and deliverance, and has become one of the leading Rolls manufacturers in India.

The Rolls division is headed by a team of professionals and technical experts having an extensive experience of more than 25 years in the Rolls industry and are capable of handling even the most critical jobs. Currently we are manufacturing Rolls and Rings of up to 1300mm in diameter and finish weight of 16 M.T.

Application

TMT

Structure

Rail

Wire Rod

HR Coil

Section

ALLOY CAST STEEL ROLLS

Characteristics : Carbon content in Alloy Cast Steel Rolls is in the range of 0.50% to 0.80%. These Hypo-eutectoid steel rolls are alloyed with Chromium and Molybdenum. The heat treatment of these rolls involve double annealing cycles followed by tempering. This helps to improve toughness and thermal shock resistance. The microstructure is primarily fine pearlitic with broken/spheroidised cementite. These rolls have high mechanical strength with good weldability.

Applications :These Rolls are suitable for Blooming Mills and Roughing Stands for Light and Heavy Section Mills.

ACS 33 (30°-35° Sh C)

ACS 37 (35°-40° Sh C)

Tensile Strength : 700-800 N/mm2

Bending Strength: 3-6 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Cr% | Mo% |

|---|---|---|---|---|---|---|

| 0.50 | 0.50 | 0.30 | 0.05 | 0.05 | 0.80 | 0.20 |

| 0.80 | 1.00 | 0.70 | MAX | MAX | 1.20 | 0.50 |

ALLOY STEEL BASE (ADAMITE) ROLLS

Characteristics :Alloy Steel Base Adamite Rolls are Hyper-eutectoid Steel alloyed with Nickel, Chromium and Molybdenum with higher Carbon content, ranging from 0.80% to 2.00%. Vanadium is also added to achieve the desired microstructure. It has higher mechanical strength and thermal/wear resistance. The rolls undergo a multi-stage, high temperature heat treatment cycle which consists of Normalising/Hardening followed by a tempering cycle. This gives the rolls a combination of hardness, toughness and wear resistance required for a particular application. The microstructure consists of fine pearlitic matrix with spheroidised carbide.

Applications :These Rolls are suitable for Roughing, Intermediate and Finishing stands for Section and Structural Mills. Applications include Heavy Section and Rail Mills, Universal Beam Mills, TMT Re-Bar and Wire Rod Mills, Medium Section Mills and Billet Mills.

ADM 37 (35°-40° Sh C)

ADM 42 (40°-45° Sh C)

ADM 47 (45°-50° Sh C)

ADM 50 (48°-52° Sh C)

Tensile Strength: 600-700 N/mm2

Bending Strength: 3-8 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Ni% | Cr% | Mo% |

|---|---|---|---|---|---|---|---|

| 0.80 | 0.60 | 0.30 | 0.05 | 0.05 | 0.50 | 0.80 | 0.25 |

| 2.00 | 1.20 | 0.80 | MAX | MAX | 1.30 | 1.60 | 0.60 |

GRAPHITIC STEEL ROLLS

Characteristics : A special type of steel roll where some properties of cast iron are included in the steel material. The service performance of this roll is superior to a normal steel roll, i.e., it is much more resistant to wear and fire cracks due to the presence of graphite without reduction of strength and toughness. These rolls are ideal for all mills like medium and heavy section where fire cracking is major concern.

Applications :These Rolls are suitable for Medium and Heavy Section Mills and Roughing Stands of TMT Re-Bar and Wire Rod Mills.

GPH 50 (48° - 52° Sh C)

GPH 53 (53° - 58° Sh C)

Tensile Strength : 650-850 N/mm2

Bending Strength : 3-9 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Ni% | Cr% | Mo% |

|---|---|---|---|---|---|---|---|

| 1.30 | 0.60 | 0.80 | 0.05 | 0.05 | 0.80 | 0.80 | 0.25 |

| 2.10 | 1.10 | 1.60 | MAX | MAX | 2.00 | 1.40 | 0.60 |

HIGH SPEED STEEL ROLLS (HSS)

Characteristics :HSS Rolls are centrifugally cast, which means that the Shell is HSS and contains high amounts of Cr, Mo, Nb, V and W and the Core is Nodular Iron. HSS Rolls have several benefits like High Hardness & Good Wear Resistance, High Campaign Life, High Abrasion Resistance, Huge Time Saved which was earlier lost to Rolls/Pass Changing, Reduced Cost of Production, Better Surface Finish of Rolled Product and Good Thermal Stability

Applications :These Rolls are suitable for Finishing Stands of Wire Rod and TMT Re-Bar Mills.

HSS 78 (75° - 80° Sh C)

HSS 83 (80° - 85° Sh C)

Tensile Strength : 650-900 N/mm2

Bending Strength : 4-8 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | Cr% | Mo% | W% | V% | Ni% |

|---|---|---|---|---|---|---|---|

| 1.60 | 0.20 | 0.30 | 4.00 | 3.50 | 2.00 | 4.00 | 0.50 |

| 2.20 | 0.80 | 0.90 | 7.00 | 6.00 | 5.00 | 6.00 | 1.50 |

SPHEROIDAL GRAPHITE IRON (FERRITIC) ROLLS

Characteristics :Spheroidal Graphite Iron Ferritic Rolls are structurally characterised as having graphite in nodular form. The matrix structure varies from Ferritic to Ferrito-Pearlitic along with low carbide content and graphite in the form of spheroid / nodules.

Applications :These rolls are suitable for Roughing Mill stands of Blooming/Slabbing, TMT Re-Bar and Wire Rod mills

SG F 43 (40° - 45° Sh C)

SG F 47 (45° - 50° Sh C)

Tensile Strength : 400-600 N/mm2

Bending Strength : 2-4 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Ni% | Cr% | Mo% |

|---|---|---|---|---|---|---|---|

| 2.80 | 0.60 | 1.50 | 0.08 | 0.015 | 1.50 | 0.10 | 0.25 |

| 3.40 | MAX | 2.30 | MAX | MAX | 2.30 | 0.60 | 0.60 |

SPHEROIDAL GRAPHITE IRON (PEARLITIC) ROLLS

Characteristics :Spheroidal Graphite Iron Pearlitic Rolls are structurally characterised as having graphite in nodular form instead of being in flakes as characterised in normal Cast Iron Rolls. The matrix structure varies from Ferrito-Pearlitic and Pearlitic together with different carbide content and graphite in the form of spheroid / nodules.

Applications :These Rolls are suitable for Roughing and Intermediate Mill Stands of Blooming/Slabbing, TMT Re-Bar and Wire Rod mills, and Rolls for Intermediate and Finishing Stands of Structure and Narrow Strip Mills.

SG P 47 (45° - 50° Sh C)

SG P 53 (50° - 55° Sh C)

SG P 57 (55° - 60° Sh C)

SG P 63 (60° - 65° Sh C)

Tensile Strength : 400-600 N/mm2

Bending Strength : 2-4 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Ni% | Cr% | Mo% |

|---|---|---|---|---|---|---|---|

| 3.00 | 0.45 | 1.20 | 0.08 | 0.015 | 1.50 | 0.30 | 0.25 |

| 3.60 | 1.10 | 2.30 | MAX | MAX | 2.30 | 0.90 | 0.50 |

SPHEROIDAL GRAPHITE IRON (BAINITIC-ACICULAR) ROLLS

Characteristics :S.G.I. Bainitic-Acicular Rolls are stronger and more wear resistant than S.G.I. Pearlitic Rolls and are capable of much higher hardness. They are alloyed with a higher % of Nickel and Molybdenum than S.G.I Pearlitic and as a result, Acicular rolls have a bainitic matrix with increased carbide. The name of this material is based on its constituents of nodular graphite and carbides in an acicular (needle-like) bainitic matrix, also called Lower Bainitic. These Rolls are very suitable for a wide range of applications due to its hardness penetration, good wear and heat resistance. Intensive water cooling of rolls is necessary to ensure best performance.

Applications :These Rolls are suitable for Intermediate and Finishing Mill Stands for TMT Re-Bar and Wire Rod Mills, Rail and Structural Mills.

SG AC 63 (60° - 65° Sh C)

SG AC 67 (65° - 70° Sh C)

SG AC 73 (70° - 75° Sh C)

Tensile Strength : 500-600 N/mm2

Bending Strength : 3-5 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Ni% | Cr% | Mo% |

|---|---|---|---|---|---|---|---|

| 3.20 | 0.45 | 1.20 | 0.06 | 0.015 | 2.30 | 0.40 | 0.40 |

| 3.70 | 1.00 | 1.60 | MAX | MAX | 3.50 | 0.90 | 1.00 |

ALLOYED INDEFINITE CHILL ROLLS (AIC)

Characteristics :Alloyed Indefinite Chill Rolls (AIC) have a matrix structure which varies from fine pearlitic to bainitic martensitic depending on the alloy addition. The desired hardness is achieved by changing the carbide to graphite balance with the help of the chemical composition. The presence of flake graphite makes the material resistant to fire cracking, spalling/chip-off and wear. Also, due to alloy addition, these rolls have a much better hardness penetration than clear chill and other cast iron rolls. Alloyed Indefinite Chill Rolls (AIC) are highly suitable for products where surface finish is very critical. Adequate water cooling of roll is required. Wide range of hardness/composition for a variety of applications is available to suit a particular mill stand.

Applications :These Rolls are suitable for Intermediate/Finishing Stands of TMT Re-Bar and Wire Rod Mills, Merchant Mills and Structural Mills. Finishing Stands of Strip and Flat Rolling Mills.

AIC 57 (55° - 60° Sh C)

AIC 63 (60° - 65° Sh C)

AIC 67 (65° - 70° Sh C)

AIC 73 (70° - 75° Sh C)

SPIC (70° - 80° Sh C)

Tensile Strength : 200-300 N/mm2

Bending Strength: 1-1.8 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Ni% | Cr% | Mo% |

|---|---|---|---|---|---|---|---|

| 3.10 | 0.50 | 0.60 | 0.10 | 0.05 | 1.50 | 0.60 | 0.25 |

| 3.60 | 1.10 | 1.70 | MAX | MIN | 3.00 | 1.50 | 0.80 |

ICDP & En-ICDP ROLLS

Characteristics :ICDP Rolls are centrifugally cast, which means that the Shell is Hard Alloyed material and contains high amounts of Cr, Mo & Ni and the Core is Softer Nodular Iron material. ICDP takes all advantages of Alloyed Indefinite Chill such as resistance to spalling, thermal cracks & wearability and gives good surface finish of rolled product, and further improves upon it by having a hard alloyed material as a working layer and a softer material at its core. This means that the softer core ensures good mechanical properties and resistance to thermal and mechanical loads.

Applications :These Rolls are suitable for Finishing Stands of Hot Strip Mill as Work Rolls.

ICDP 73 (70° - 75° Sh C)

ICDP 78 (75° - 80° Sh C)

ICDP 83 (80° - 85° Sh C)

Tensile Strength : 400-450 N/mm2

Bending Strength: 1-2 J/cm2

Chemical Composition Range

| C% | Mn% | Si% | P% | S% | Ni% | Cr% | Mo% |

|---|---|---|---|---|---|---|---|

| 3.00 | 0.60 | 0.80 | 0.10 | 0.05 | 3.50 | 1.00 | 0.40 |

| 3.50 | 1.20 | 1.20 | MAX | MIN | 4.00 | 1.50 | 0.65 |