ENGINEERING CASTINGS

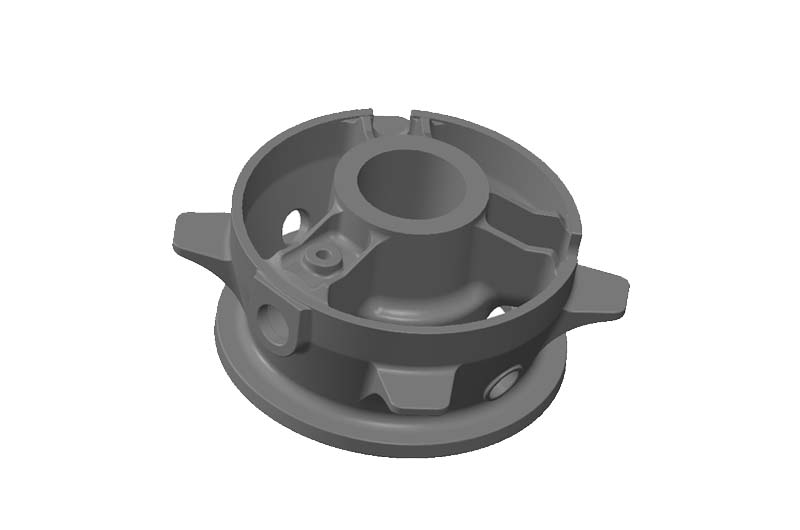

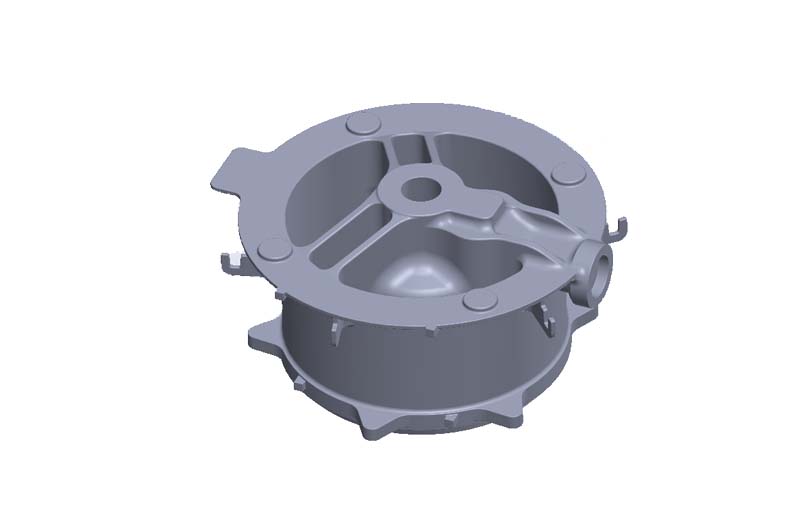

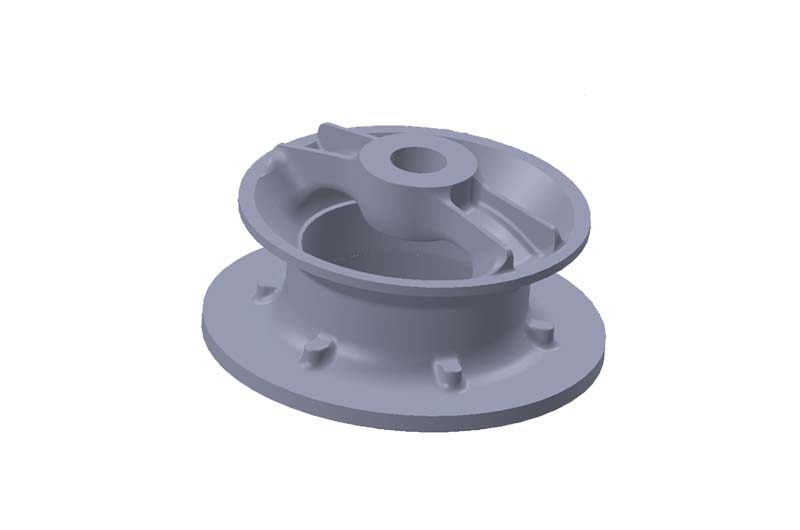

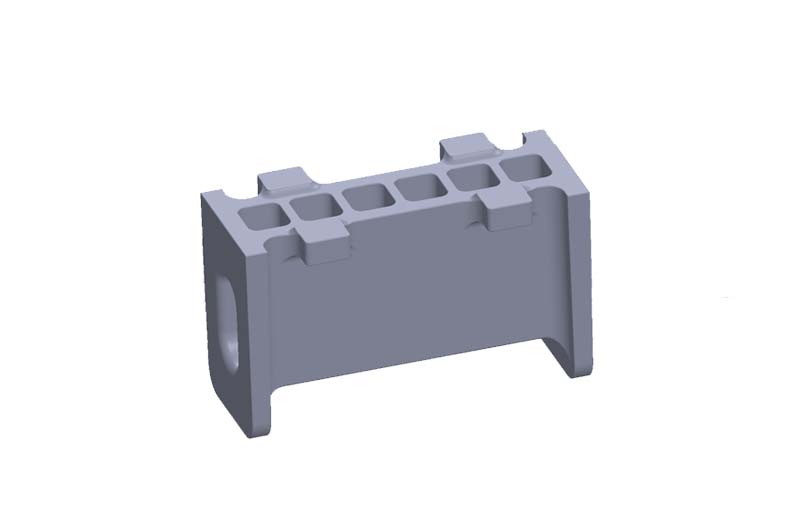

Behari Lal Group is engaged in manufacturing of Engineering Castings in various grades for core industrial sectors like Steel, Mining, Automotive, Infrastructure, Cement, Sugar, Rubber, Wind Energy Projects, Paper Mills, Railways, Forging, Hydroelectric Dam Projects, Sponge Iron, Thermal Energy Projects, Machine Building and other specialised areas in Pre-Machined and Finish Machined Condition. We are a fully integrated Foundry with all processes including Engineering, Pattern Making, Moulding, Melting, Fettling, Heat Treatment, Machining, Finishing and Final Inspection - all under one roof. We are manufacturing critical castings in special grades with per unit weight ranging from 500kgs to 20 M.T.

Application

Steel

Mining

Automotive

Infrastructure

Cement

Sugar

Hydroelectric Dam Projects

Sponge Iron

Thermal Energy Projects

We are manufacturing the following material grades and fulfill all the parameters as per the requirement of the customer:

| Carbon Steel | Alloy Steel | ||||

|---|---|---|---|---|---|

| # | Standard | Grade | # | Standard | Grade |

| 1 | EN 10293:2015 | GE200 | 1 | ASTM A217 | Grade WC6 |

| 2 | EN 10293:2015 | GE240 | 2 | ASTM A217 | Grade WC9 |

| 3 | EN 10293:2015 | GS240 | 3 | EN 10293:2015 | G10MnMoV6-3 |

| 4 | EN 10293:2015 | GE300 | 4 | ASTM A148 | Grade 80-50 |

| 5 | EN 10293:2015 | G20Mn5 | 5 | ASTM A148 | Grade 90-60 |

| 6 | DIN 1681 | GS-45 | 6 | ASTM A148 | Grade 105-85 |

| 7 | DIN 1681 | GS-52 | 7 | IS 2644:1994 | All Grades |

| 8 | DIN 1681 | GS-60 | 8 | BS970: 1955 | EN 19 |

| 9 | IS 2708:1993 | All Grades | 9 | BS970: 1955 | EN 24 |

| 10 | EN 10293:2015 | GE 240+N | 10 | EN 10293:2015 | G34CrMo4 |

| 11 | IS 1030:1998 | All Grades | 11 | EN 10293:2015 | G42CrMo4 |

| 12 | ASTM A148 | Grade 80-40 | 12 | EN 10293:2015 | G35CrNiMo6-6 |

| 13 | ASTM A216 | Grade WCA | 13 | IS 4896:1992 | All Grades |

| 14 | ASTM A216 | Grade WCB | 14 | PN H83161 | PN L70H2GNM |

| 15 | ASTM A216 | Grade WCC | 15 | ASTM A743 | CA6NM |

| 16 | ASTM A27 | Grade 60-30 | 16 | ASTM A743 | CA15 |

| 17 | ASTM A27 | Grade 70-36 | 17 | BS3100:1991 | BT1-BT3 |

| 18 | ASTM A27 | Grade 70-40 | |||

| 19 | BS970: 1955 | EN 8 | |||

| 20 | IS 2707:1996 | All Grades | |||

| 21 | BS970: 1955 | EN 9 | |||

| 22 | BS3100:1991 | A1-A6 | |||

| 23 | IS2708:1993 | All Grades | |||

| STANDARD | |||

|---|---|---|---|

| IS 210:2009 | EN 1561:2011 | ISO 185:2020 | ASTM A48 |

| GRADE | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | FG 260 | EN-GJL-250 | JL/250 | 250 | |||||||

| 2 | FG 300 | EN-GJL-300 | JL/300 | 300 | |||||||

| 3 | FG 350 | EN-GJL-350 | JL/350 | 350 | |||||||

| SG IRON/NODULAR IRON | |||

|---|---|---|---|

| STANDARD | |||

| IS 1865:1991 | EN 1563:2018 | ISO 1083:2018 | ASTM A536 |

| GRADE | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | SG 400/15 | EN-GJS-400-15 | JS/400-15 | - | |||||||

| 2 | SG 450/10 | EN-GJS-450-10 | JS/450-10 | 65-45-12 | |||||||

| 3 | SG 500/7 | EN-GJS-500-7 | JS/500-7 | 70-50-05 | |||||||

| 4 | - | - | JS/550-5 | 80-55-06 | |||||||

| 5 | SG 600/3 | EN-GJS-600-3 | JS/600-3 | 80-60-03 | |||||||

| 6 | SG 700/2 | EN-GJS-700-2 | JS/700-2 | - | |||||||

| 7 | SG 800/2 | EN-GJS-800-2 | JS/800-2 | - | |||||||

We can manufacture any other grade as per customer’s specific requirement

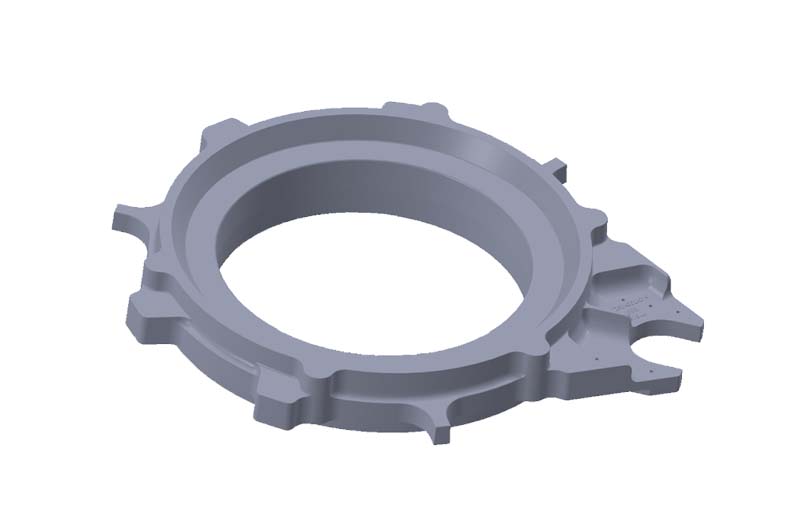

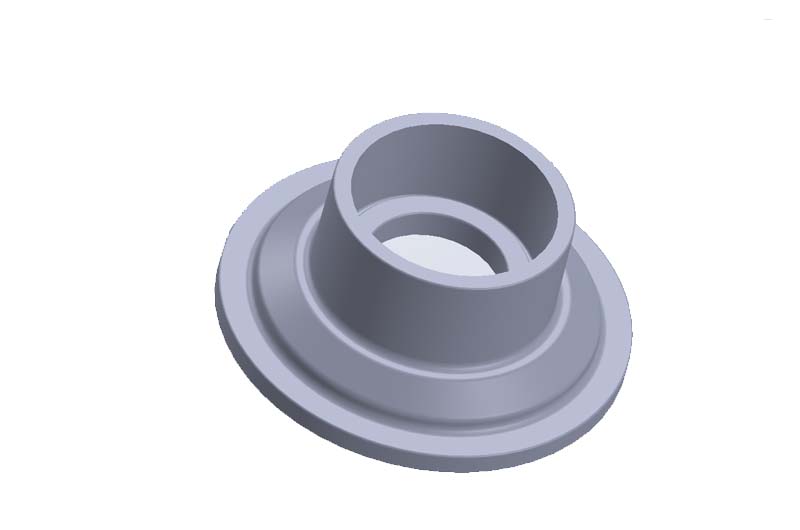

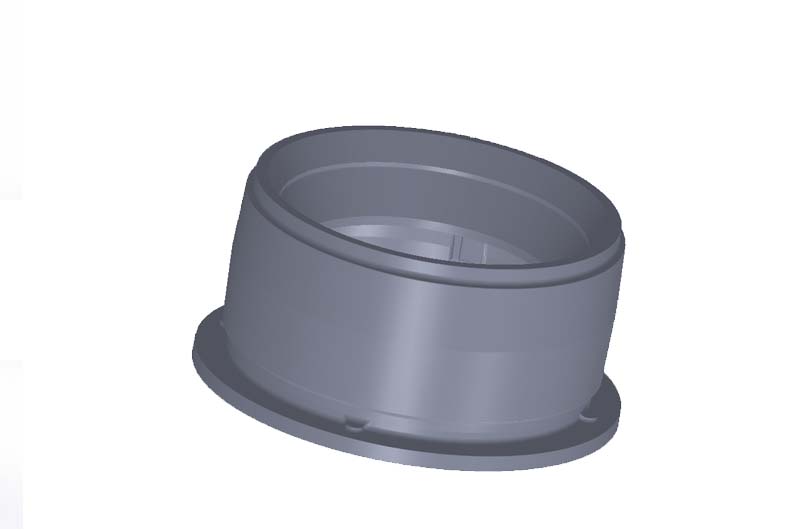

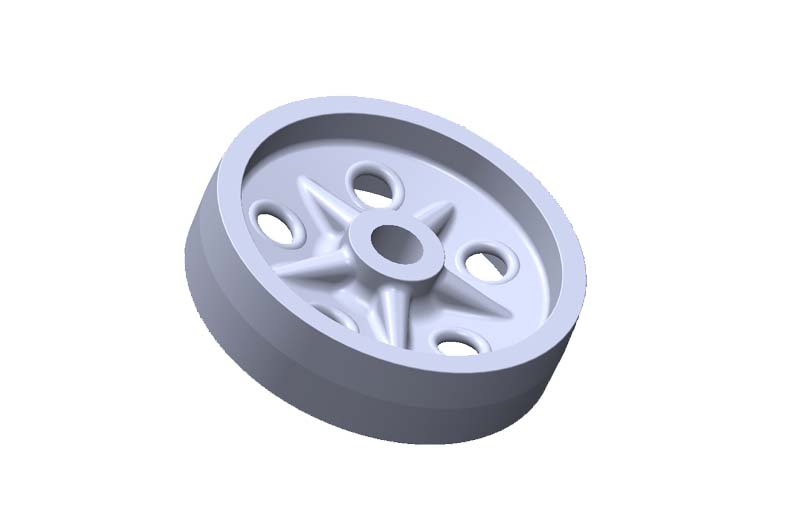

Some of the components being manufactured are :

Adjustment Ring, Base Plate, Bearing Block, Bearing Housing, Bed Casting, Bed Plate, Bell, Bonnet, Bottom Shell, Bowl, Bull Gear, Bush Bearing, Bushing Retainer, Caps, Carrying Roller, Chocks, Clay Barrel, Column, Counter Shaft, Cross Slide, Diaphragm Plate, Dies, End Cup, Floor Plate, Fly Wheel, Front End Frame, Full Mould, Gantry Project, Gear, Girth Gear, Head, Head Stock, Hopper, Hub, Journal Head, Journal Housing, Lower Frame, Lower Journal Bearing Retainer, Main Beam, Main Frame, Mill Cap, Mill Frame, Mill Head, Mill Housing, Mill Liner, Mill Stand, Nozzle Ring Segment, Pinion, Piston Housing, Pitman, Plates, Rake Wheel, Rear End Frame, Reducing Pipe, Reduction Gear, Retainer, Ring, Roller, Roller Shell, Rope Drum, Slag Pots, Socket, Sprocket, Spur Gear, SS Pin, Support Roller, Surface Plate, Table, Tail Stock, Toggle Beam, Top Shell, Trunnion, Trunnion Hub, Tyre, Upper Frame, etc.